info@maxim-corp.com

+8613771990522

Boost Your Warp Knitting Efficiency with Lightweight Precision Technology

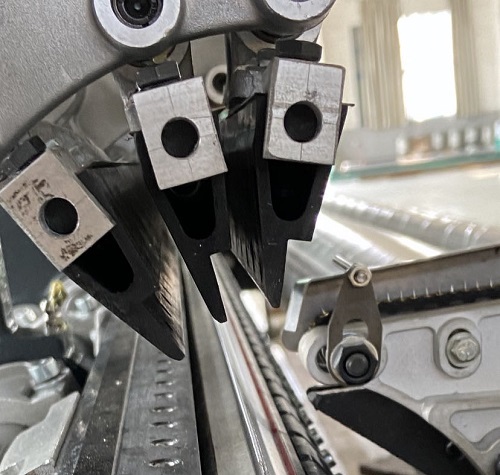

In the competitive world of warp knitting, every component of your machine matters—especially the needle bar. As global textile manufacturers seek faster speeds, higher precision, and greater durability, the carbon fiber compound needle bar has emerged as a next-generation solution that dramatically enhances both performance and productivity.

Combining the superior mechanical properties of carbon fiber with cutting-edge engineering, this compound needle bar offers an unmatched strength-to-weight ratio, reduced machine stress, and consistent high-speed performance across various warp knitting applications.

Why Carbon Fiber for Warp Knitting Needle Bars?

The traditional metal needle bars, while robust, often contribute to machine vibration, increased wear, and limited speed. In contrast, carbon fiber needle bars deliver a lightweight yet incredibly rigid structure that solves many of these challenges, especially in high-speed tricot and raschel warp knitting machines.

🔍 Key Advantages of the Carbon Fiber Compound Needle Bar

✅ Ultra-Lightweight with High Rigidity

The carbon fiber material reduces the overall weight of the needle bar system without compromising structural strength. This leads to smoother operations and less mechanical strain on the knitting machine.

Optimized for high-frequency movement, the carbon fiber compound needle bar ensures precise

needle alignment and low vibration,

enabling faster knitting cycles and improved fabric uniformity.

Optimized for high-frequency movement, the carbon fiber compound needle bar ensures precise

needle alignment and low vibration,

enabling faster knitting cycles and improved fabric uniformity.

✅ Extended Service Life & Lower Maintenance

Thanks to its resistance to corrosion, fatigue, and thermal distortion, this needle bar endures prolonged use even in demanding environments, translating to lower operational costs and fewer breakdowns.

✅ Reduced Load on Machine Mechanics

The lightweight nature helps reduce inertia and load on the drive components, significantly extending the life span of other key machine parts and improving overall system reliability.

🧵 Applications Across Warp Knitting Production

If you're operating a warp knitting facility focused on output quality and machine efficiency, the tube guide needle is a critical upgrade. It ensures smoother yarn flow, fewer production errors, and ultimately, higher-quality textiles.

This high-performance compound needle bar is suitable for a wide range of warp knitting machines, including but not limited to:

It’s especially ideal for the production of technical textiles, sportswear fabrics, mesh, lace, automotive textiles, and industrial fabrics that demand precise and repeatable stitch quality at high speed.

🌍 Trusted by Leading Warp Knitting Manufacturers Worldwide

🌍 Trusted by Leading Warp Knitting Manufacturers Worldwide

Whether you're producing lace fabrics or engineered mesh, the carbon fiber compound needle bar is a reliable upgrade trusted by textile companies in Europe, Asia, and the Americas. Backed by proven results in diverse production environments, it helps maintain consistent product quality while supporting faster delivery schedules.

🔧 Product Configurations & Support

📈 Unlock New Levels of Productivity & Fabric Excellence

Upgrading to the carbon fiber compound needle bar is more than a parts replacement—it's a strategic investment in the future of your warp knitting operation. With improved speed, precision, and durability, your machines will operate more efficiently, with fewer interruptions and better end-product results.

🔗 Request a Quote or Technical Consultation

Ready to modernize your warp knitting machine setup? Contact us today for detailed specifications, compatibility checks, and pricing. Let us help you optimize your production with a needle bar solution engineered for performance and longevity.

#CarbonFiberNeedleBar #CompoundNeedleBar #WarpKnittingMachineParts #High-speedKnitting #TricotMachineUpgrade #RaschelNeedleBar #TextileMachineComponents #WarpKnittingTechnology #PrecisionKnittingEquipment