info@maxim-corp.com

+8613771990522

Jacquard technology is redefining the future of warp knitting machines, driving innovation across the textile industry by delivering unprecedented precision, flexibility, and design capability. This groundbreaking integration is transforming not only the way textiles are manufactured but also expanding the creative possibilities available to designers and manufacturers alike.

The Evolution of Warp Knitting Machines

Traditionally, warp knitting machines have played a central role in textile production, offering high-speed and cost-efficient fabrication of a wide range of fabrics. In a warp knitting machine, warp threads are held under tension and interlaced with weft threads to create fabric structures. Historically, these machines used mechanical pattern chains or punch cards to control the movement of warp threads. While effective, such systems limited the complexity and variation of design.

Enter Jacquard: Precision Thread Control

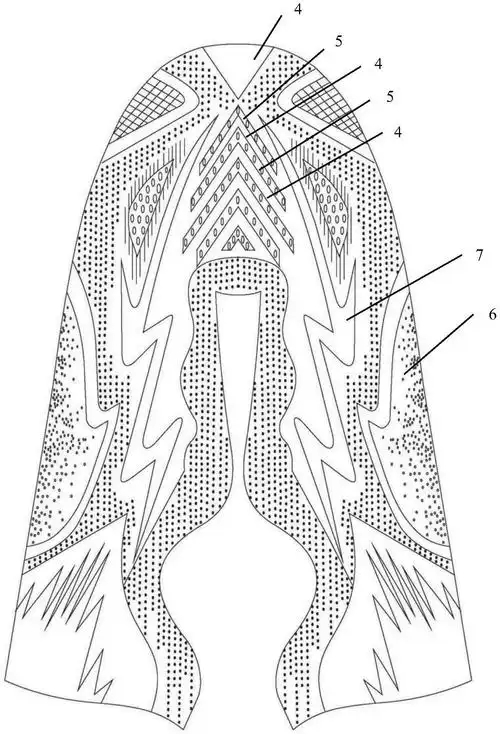

The introduction of Jacquard technology—named after French inventor Joseph Marie Jacquard—marks a major milestone in the evolution of warp knitting. Jacquard systems allow for individual control of warp threads using electronically actuated needles or hooks. This advancement enables the creation of intricate patterns, detailed motifs, and even photorealistic images, all seamlessly integrated into the fabric during the knitting process.

Transforming Textile Design and Production。

With Jacquard integration, warp knitting machines now offer textile designers and fashion brands unparalleled creative freedom. What once required complex setups or multiple production stages can now be achieved in a single, efficient manufacturing run. The ability to manipulate individual warp threads means:

This leads to more sustainable production processes while also accelerating time-to-market.

Applications Across Industries

The benefits of Jacquard-enabled warp knitting extend well beyond the fashion industry. Today, these advanced machines are utilized in:

• Technical textiles (e.g., filtration, geotextiles, medical fabrics)

• Home furnishings (e.g., curtains, upholstery, decorative fabrics)

• Automotive interiors (e.g., seat covers, trim fabrics)

• High-performance materials (e.g., carbon fiber textiles and composites)

The precision and versatility of Jacquard technology enable manufacturers to tailor fabric characteristics to meet specific performance criteria across diverse industrial sectors.

The precision and versatility of Jacquard technology enable manufacturers to tailor fabric characteristics to meet specific performance criteria across diverse industrial sectors.

A New Standard for the Future

As the textile industry embraces smart manufacturing and digital innovation, the Jacquard warp knitting machine is becoming a benchmark for advanced production. This synergy of tradition and technology benefits manufacturers with greater operational efficiency, empowers designers with limitless pattern options, and delivers to end-users a new standard in fabric quality and functionality.

Whether you're in fashion, home textiles, or technical materials, the integration of Jacquard technology into warp knitting machines offers a compelling path toward innovation, customization, and sustainable growth.

> #Jacquard #Piezo #GuideNeedle #WarpKnitting #Textile