info@maxim-corp.com

+8613771990522

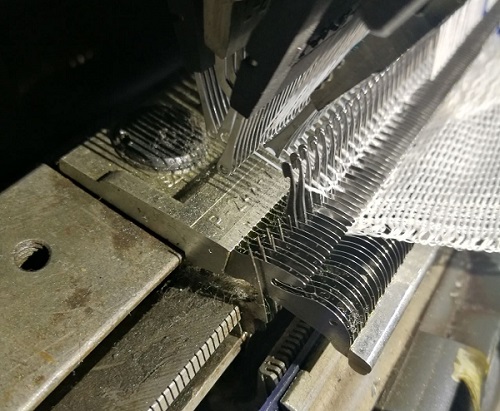

In the warp knitting industry, every component plays a crucial role in ensuring consistent, high-quality textile production. Among these, the tongue bar is a key mechanical part responsible for yarn loop formation and stitch accuracy. At high-speed operations, a durable and precisely engineered tongue bar ensures seamless performance, optimal fabric structure, and minimal downtime.

Our high-performance tongue bars are specifically designed to meet the rigorous demands of modern warp knitting machines, whether you're running tricot or raschel models. With exact fitment, advanced material construction, and a polished finish, our tongue bars offer outstanding loop control, reduced yarn wear, and superior fabric quality—ideal for both delicate and technical textile applications.

🔩 Product Overview: What Is a Tongue Bar?.

A tongue bar is a structural knitting element located between the knitting needles and sinkers. It plays a vital role in guiding and supporting yarn loops during the warp knitting process, especially in high-speed textile production environments.

Manufactured with tight engineering tolerances and high-strength materials, the tongue bar ensures stability, precise stitch formation, and prolonged machine life. Whether you're producing stretch lace, rigid mesh, or complex technical textiles, a well-made tongue bar is essential for maintaining consistent product quality.

✅ Key Features & Advantages

🔧 High-Precision Engineering

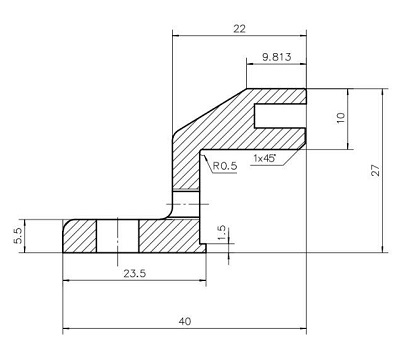

Every tongue bar is produced with CNC-level accuracy to ensure flawless alignment with other knitting elements. This guarantees smooth operation, minimized mechanical friction, and consistent yarn loop formation.

💎 Durable, Wear-Resistant Alloys

Made from premium-grade steel or custom alloys, our tongue bars are heat-treated and hardened for extended wear resistance. This reduces part replacement frequency and keeps your production lines running longer with fewer interruptions.

✨ Polished Surface for Smooth Yarn Handling

The surface of each bar is finely polished to minimize yarn snagging, abrasion, and shedding—resulting in cleaner stitch transfer and enhanced fabric quality across all materials, including synthetic, blended, and fine-gauge yarns.

🔄 Universal Compatibility

Designed to integrate seamlessly with a wide range of warp knitting machines—including leading brands like KARL MAYER, LIBA—our tongue bars are available in various sizes and profiles to match tricot and raschel machine specifications.

🧵 Applications Across the Warp Knitting Industry

Our tongue bars are widely used in warp knitting operations involving:

Thanks to their robust design and high-speed performance, they are ideal for both mass production environments and niche textile manufacturing where stitch uniformity and loop precision are critical.

🌍 Why Global Manufacturers Trust Our Tongue Bars

Choosing the right tongue bar isn’t just about replacement—it's about investing in machine stability, fabric consistency, and operational efficiency. With our precision-crafted tongue bars, you gain a competitive edge through superior loop control, longer componecnt life, and minimal production disruptions.

Whether you're manufacturing high-volume mesh fabric or specialty technical textiles, our tongue bars are the reliable choice trusted by textile professionals worldwide.

#WarpKnittingMachineTongueBar #TongueBarForRaschelMachine #TricotTongueBar #warpknittingyarnguideparts #high-speedknittingmachinecomponents #textilemachineryspareparts